Home / Comprehensive Pallet Racking Inspection Services

We provide quick, convenient, and non-disruptive pallet racking inspections that comply with Australian and New Zealand safety standards. Regular inspections keep your staff and inventory safe and also ensure your racking meets all local and international safety requirements.

Our warehouse safety audits are a proactive measure against warehouse accidents and injury, while securing the integrity and performance of your pallet racking systems.

Pallet racking inspections are essential to maintaining a safe work environment for you and your staff.

In warehousing, transportation and retail industries, your pallet racking is one of your biggest assets. You rely on pallet racking to provide you with a convenient storage solution that saves space and aids in inventory management and transport.

Racking inspections therefore play a crucial role in the maintenance of your pallet racking systems. Inspections should be made annually or bi-annualy and conducted by certified experts.

Warehouse racking inspections may be a top priority for many employers, but it is also a legal obligation to ensure the continued safety and performance of your pallet systems.

We can set up a comprehensive pallet racking inspection schedule for you and provide you with a professional, independent auditor who will determine the safety of your systems and provide you with in-depth maintenance recommendations.

The process is performed on-site and is non-disruptive to your operations.

As warehouse owners and operators, it is both a legal and a moral obligation to ensure the safety of your pallet racking systems. Pallet racking safety inspections ensure the integrity and continued performance of your warehouse racking systems. They are also crucial to ensuring the safety and wellbeing of your staff and operators as they handle heavy-duty loads and materials.

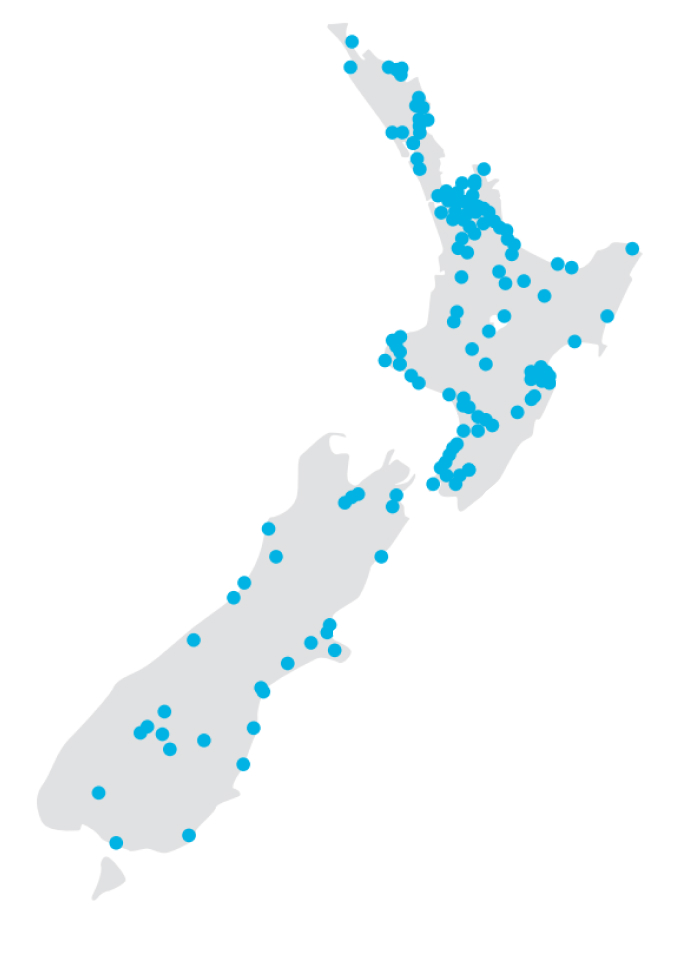

Warehouses are especially vulnerable to damage given the seismic conditions in New Zealand. Your shelves and storage systems must be fully equipped to withstand natural disasters as well as to meet New Zealand’s legal requirements.

You need to audit your pallet racking in order to comply with New Zealand rack design and safety laws. Auditing will also streamline any insurance or warranty claims that you may need to make by providing you with full documentation.

Pallet racking safety inspections maximise employee safety by using a proactive approach to maintenance. This will ensure the longevity of your pallet racking systems and prevent costly repairs down the line. It also ensures that your system is not exceeding its load capacity, which guarantees the stability of your system.

Australia launched a new pallet racking standard on 12 May 2023. Because New Zealand does not have a unique pallet racking standard, we refer to Australia’s standards. This new standard is AS4084.

One of the most notable updates to the new standard is the requirement to have an independent assessor conduct a formal inspection. It no longer permissable to conduct your own in-house inspections.

The other notable update to the standard is that it is mandatory to complete an annual racking inspection. To ensure compliance with AS 4084:2:2023, it is mandatory for a formal inspection to be performed by a competent external provider every 12 months.

If you manage a warehouse, you know how important audits are. Warehouse safety audits involve checking inventory, examine current productivity, inspecting the entire facility for safety issues as well as develop strategies to enhance operations. This way, you can evaluate the performance of your warehouse and find out in which areas you need to improve.

An audit lets you keep track of how things are doing in your warehouse and lets you prevent potential harm from any safety risks that may lurk in your facility. You can also cut down on repair and maintenance expenses by rack safety inspections. This allows you to fix or replace faulty equipment before it causes any damage.

The steps of a safety audit include:

Step 1: Examine the warehouse and identify areas that need improvement

Step 2: Review existing safety measures and find the gaps

Step 3: Develop processes, systems and solutions that help address the gaps

Shelving Shop provides a wide range of pallet racking and display shelving for warehouses, as well as the commercial and retail industries. Our racking inspection services are our guarantee that your racking continues to be safe, functional and in line with New Zealand legal requirements.

Contact us today and set up an inspection schedule with one of our trusted, auditors.